Prevent electrical fires

Spot electrical problems and avoid fires

Sprinklers. Extinguishers. Alarms. You take many precautions to avoid fire in your business. But perhaps the best thing you can do is look for sources of fires before they start. Statistics from the National Fire Protection Association show that one of the top causes of fires is electrical issues in your building. Often, it’s because of problem wiring. Once issues are discovered, you can make corrections. We’ve discovered some common things for you to look for:

Junction boxes

Connections to junction boxes should be secured with mechanical fasteners—including lock nuts and bushings. You should look to see that the connection holds securely, but not too tight to damage the wire's insulation before, during, or after installation. Loose connections can allow the wire to move, causing damage to the wire's insulation and letting unwanted material into the box.

Not only do electrical boxes provide protection from wiring damage, metal conduit systems may also serve as an equipment grounding conductor. You should look for broken or loose connections that can interrupt the continuity or create a high resistance junction, nullifying the shock protection provided by the equipment grounding conductor.

Extension cords

Extension cords are intended to be used no more than two weeks and shouldn’t be used in place of permanent wiring. If you have to tack, staple, or nail an extension cord in place, what you really need to do is install permanent wiring instead. In this example, the extension cord around the door could be replaced with a conduit. Be sure to follow the National Electrical Code (NEC) when installing any permanent wiring.

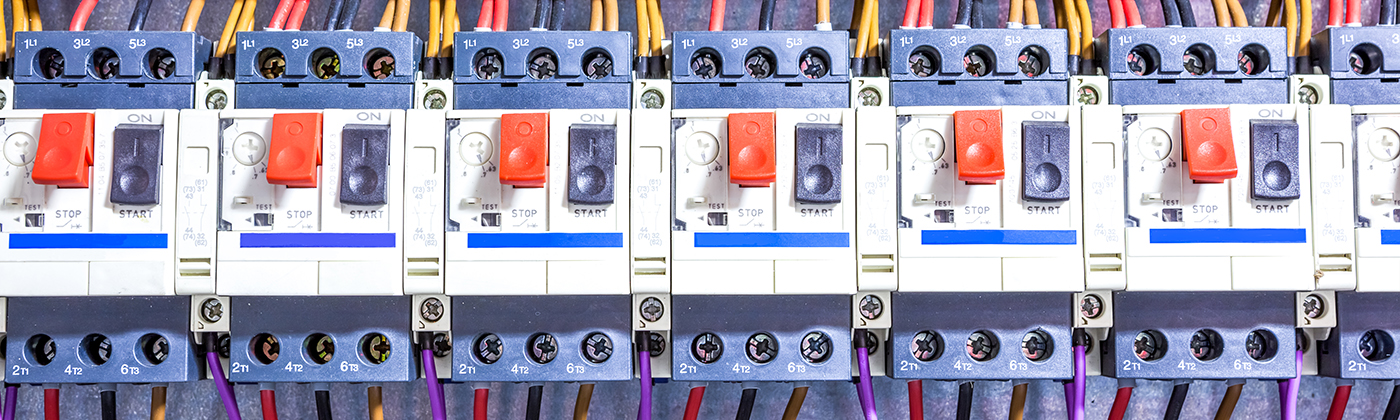

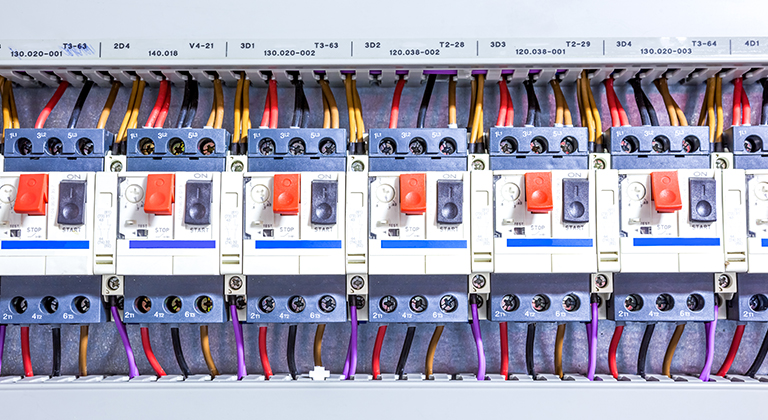

Fixed electrical equipment

Wiring to your fixed electrical equipment—especially motors on vibrating equipment—can easily become defective or damaged. Flexible conduit can pull or work loose from junction boxes. Box covers can be left off or screws can vibrate loose. All of this can cause excessive wear and deterioration to the wire's connections and insulation. But that’s not all, an open cover can let in dirt, oil, moisture, and other damaging contaminants.

Temporary wiring

Like extension cords, temporary wiring installations can be easily abused and are often allowed longer than safety dictates. All too often, temporary wiring is used to service a permanent electrical need. By its very nature, temporary wiring can be damaged and deteriorate rapidly because the insulated conductors are usually exposed and unprotected. The NEC has specific requirements you should follow for the use of temporary wiring.

Overloaded outlets

When doing your examination, look for overloaded convenience outlets or light sockets converted to electrical outlets. These are often described as bottleneck wiring. When this happens, it can lead to overloaded branch circuits—especially if these circuits are protected by fuses. To avoid bottleneck wiring, add extra convenience outlets and perhaps additional circuits.

Poorly installed wires

Nonmetallic sheathed cable, armored cable, and conduit-based wiring should be securely fastened to your building’s structural members at frequent intervals. You should check with the NEC for specific support requirements. In addition, avoid using building wiring as a means of support or as a storage rack for other materials. Never tap an appliance cord into an electrical junction box and make sure it has a cover and empty knockout openings are closed.

By following these steps and taking a closer look at your wiring and electricity use around your business, you’ll be better prepared to help avoid some of the risks and fire hazards electricity can cause. A Sentry Safety specialist can explain other ways to help protect your business.

Related resources

Protecting a customer’s financial information

Keeping customers’ sensitive financial information secure from thieves is a challenge for any business. But there are ways to help you do it. We have some tips.

Limiting exposure to dangerous silica

There are many ways for workers to be exposed to crystalline silica, and all pose a health risk. We’ll help explain the dangers and the safety rules.